1. The production process of film paper is pollution-free, and the raw materials do not need wood and natural plant fibers, which can save a lot of forest resources and reduce environmental pollution.

2. Light weight, high strength, tear resistance, paper whiteness and opacity can reach more than 90%, good shielding performance, UV stability, durable.

3. Smooth surface, stable size, excellent printing performance, good printability, heat transfer printing can also be performed on the surface with special coating, or it is suitable for writing marks on the surface, such as pencils, ballpoint pens, etc.

4. The processing performance is good, and processing methods such as cutting, die-cutting, embossing, bronzing, drilling, sewing, folding, and gluing can be used.

5. Long storage period, anti-moth, waterproof, anti-chemical corrosion, anti-grease.

6. Direct contact with food is allowed.

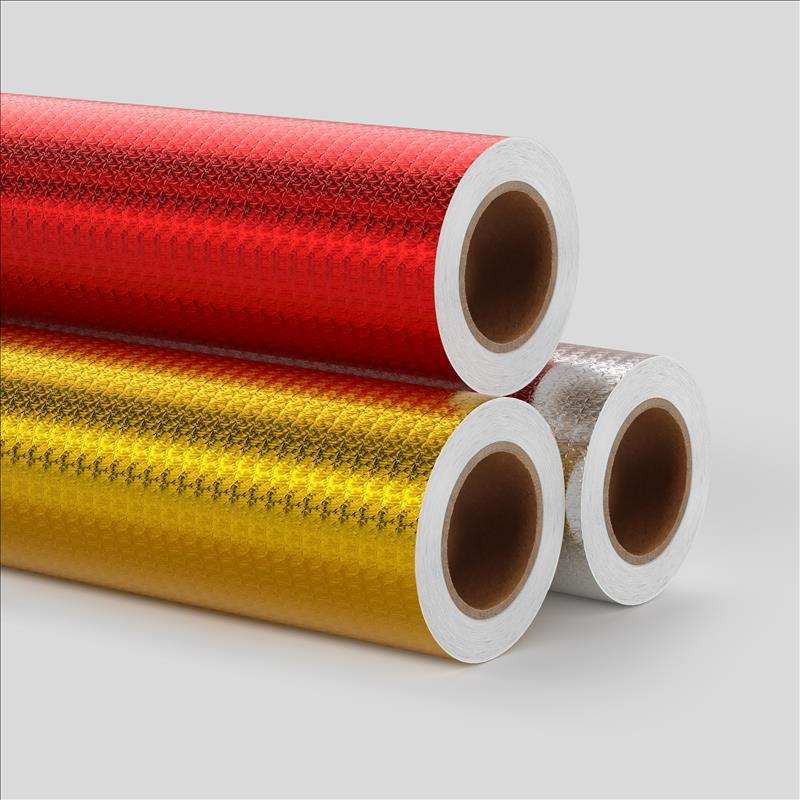

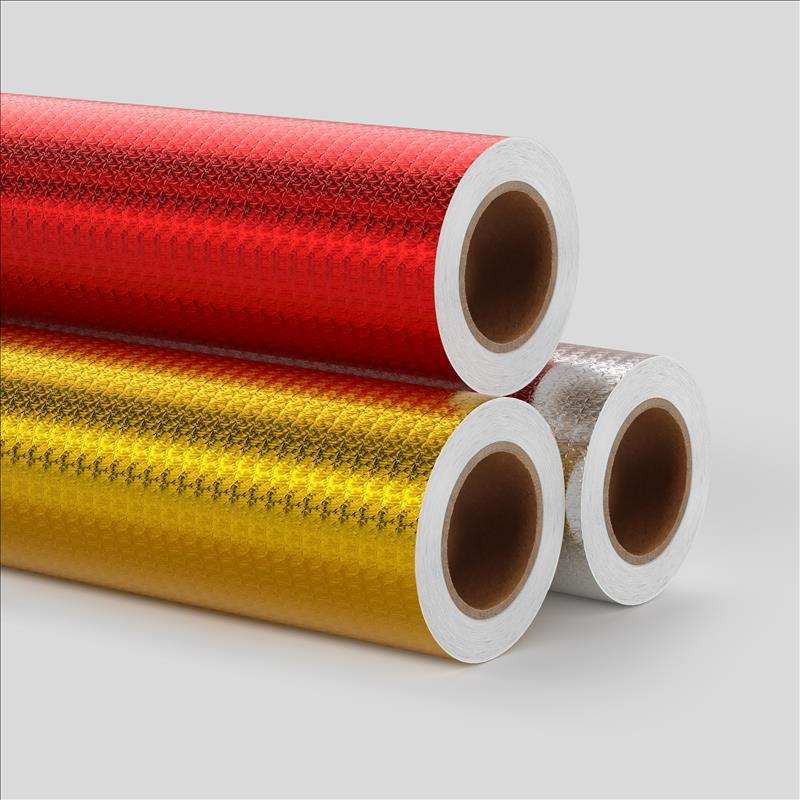

Film paper is a film material with a thickness of less than 1 micron. This special-purpose paper is called synthetic paper, also known as chemical film paper, polymer paper, plastic paper, etc. Its main raw materials are polyethylene, polypropylene, polystyrene and other organic materials. resin.

Film paper structure

The film material has the same structure as the paper material, the only difference is that the surface of the film paper needs to be treated.

Surface properties and treatment methods of film paper

The principle of the ink layer forming a pattern on the printed matter is penetration, volatilization, condensation and curing. Due to the high film density, the ink will only evaporate and form a film. There is no penetration during curing, so the surface of the film requires special treatment. The function of the surface treatment is to increase the surface tension of the film, making it greater than that of the ink, so as to achieve the correct combination of ink and film materials. Surface treatment usually adopts the following methods:

A. Corona treatment: Discharge treatment on the surface of the film through high-voltage charges, and finally achieve the purpose of increasing the surface energy, that is, the surface tension. Corona treatment is usually performed in film manufacturing plants. Since surface tension is time-bound, it must be rigorously tested before printing. Therefore, some advanced equipment has pre-press corona treatment equipment to print high-quality film products.

B. Printing treatment: Use chemical methods to change the surface characteristics of the film to make it suitable for ink printing or ribbon printing.

C. Surface coating: use chemicals to coat the surface of the film to increase surface tension and change surface characteristics.

It is widely used in the packaging and printing of labels, topographic maps, brochures, periodicals and magazines.

Tel.: +86-0755-82471177, +86-0755-27360110

Address: Building B and Building 101, No.189, Tengfeng Avenue, Fenghuang Community,

Fuyong Street, Bao'an District, Shenzhen

Dongguan Factory

Tel.: +86-13509663610

Address: No. 10, Wangniudun Xinlian Road, Wangniudun Town, Dongguan City

(Newton Intelligent Manufacturing Industrial Park)