0755-82471177

The adhesive label was first started in some coastal areas such as Guangdong and Tianjin in China, and the early equipment was also introduced into Japan. With the gradual promotion of self-adhesive labels throughout the country, our technology in all aspects has gradually matured. This year, we have become a new force. Therefore, many countries and enterprises have also welcomed the transformation and investment.

Analysis of China's label market - diversified development and broad market

China's label industry is only in its infancy. At present, the size of China's self-adhesive label market is about 450 million to 500 million square meters, and the per capita share is only 0.3 square meters/person/year. The production capacity of Hong Kong and Guangdong accounted for 67% of the whole Chinese sticker market. It is estimated that in four or five years, Shanghai will become China's largest self-adhesive label market, but the current focus is on Guangdong. Therefore, China's self-adhesive label market has huge potential!

Labels are mainly used in five fields, including decoration, information, identification, anti-counterfeiting, storage and transportation. Industries and products with more applications are mainly: daily chemicals, cosmetics, electronic appliances, medicine, daily necessities, food and beverage, supermarket retail and logistics, industrial related products, safety, anti-counterfeiting related products, environmental protection related products, etc. From the current market situation, the demand for labels in the following four industries is particularly prominent:

Daily chemical industry

According to statistics, the demand for self-adhesive labels of daily chemical products accounts for more than 30% of the total market demand, and 40% of the packaging materials of daily chemical products use self-adhesive labels. Because most of the products in the daily chemical industry are sold directly on the counter without other forms of outer packaging, the label has become the most important form of product expression. For example, with the increasing popularity of liquid detergent products in daily chemical products, more and more self-adhesive labels are used on the bottles for these automatic filling products in the form of packaging.

Electronics and electrical appliances

You can see stickers with various appearances on many electrical appliances. These labels have large unit area and many types. In addition, with the rapid popularization of IT products (computers, electronic communication products), self-adhesive labels will also be widely used as the identification of such products.

Pharmaceutical industry

With the OTC sales of over-the-counter drugs, drug manufacturers and consumers will also pay more attention to the hygiene and aesthetics of drug packaging. Drug packaging has increasingly used self-adhesive labels, which has promoted drug manufacturers to accelerate the pace of conversion from traditional labels to self-adhesive labels.

Logistics industry

In recent years, with the rapid rise of the logistics industry in China, modern logistics has an increasingly strong demand for variable information printing labels, such as storage and transportation labels, luggage labels and supermarket labels.

High quality, high information content, novel, anti-counterfeiting and environment-friendly labels are gradually being accepted by Chinese enterprises. The development direction of domestic label printing is consistent with the international trend, mainly showing the following characteristics:

High speed printing

The increasingly fierce competition and the urgency to meet the demand force label printing manufacturers to accelerate printing speed on the premise of ensuring printing quality in order to cooperate with large-scale centralized production.

Exquisite design

With the improvement of product quality, more and more exquisite labels that can convey as much product information as possible are needed. Some labels even require artistic appeal.

Various forms

Nowadays, the trend of label development is to tend to individualize, emphasize novelty and improve the amount of information. Labels are no longer just for bottle pasting. They are required to be more three-dimensional and have various shapes. Some products even need to include information such as scratch open incentive promotions.

Increased scientific and technological content

It is mainly manifested in intelligence and anti-counterfeiting. Smart tags can not only replace bar codes, but also be used in the service industry and logistics management, such as air baggage tags, book tags, highway non-stop charging instructions, and also have anti-counterfeiting functions.

Flexographic printing promotes the progress of label technology

The better appearance of labels is not only due to better matrix materials. If you ask a processor, he will tell you that the printing process is also important, especially flexographic printing, which greatly improves the appearance of the label. At present, the product quality of printers is unimaginable in the industry a few years ago. The quality of printing is becoming more and more stable due to the improvement of various technologies before, during and after printing.

All aspects of technological progress are helpful to the popularity of labels, and these advances are all to meet manufacturers' needs for more distinctive and high-quality label patterns. Each product makes the best use of the patterns and colors on the label to attract consumers. Flexographic printing gives labels some effects that can only be achieved by screen printing before. Flexographic printing could not achieve the tactile effect at first, but later, due to the use of ultraviolet curing technology, the ink was more thick, so it achieved the effect similar to that of screen printed labels. At present, many cosmetic manufacturers prefer this kind of ultraviolet printing label, because the cost is lower, and it can also be printed online and embossed with aluminum foil. The printing resolution of UV flexographic printing technology is also higher than that of screen printing.

In addition, quality control is also one of the advantages of flexographic printing machines in recent years. It is not so much an art as a science to control the calibration of the printing color of labels in different operation batches. At present, the color difference of labels that purchasers get each time has been very subtle, which is very important for some companies. In particular, some companies have many kinds of products, and each label color corresponds to a certain product color. The label provides great flexibility, so some manufacturers can use it alone or in combination with the screen, with a wide range of options.

At present, the printing industry is gradually accepting color management technology to help designers be more accurate in color. In the future, the color and quality of labels will be more stable, and the differences between different batches of products will be undetectable. In addition to better color control, printing equipment has made progress in such aspects as screen printing, color register and plate making, which have improved the bright and three-dimensional sense of printing patterns. Cosmetics manufacturers want their products to be different. They expect label processors to provide attractive designs and products. Flexographic printing technology gives them the answers they need.

With the progress of technology, we can see the characteristics of label processing technology:

1. In terms of technology and design, the printing pattern changes from monochrome to multi-color, and develops from simple color blocks, lines and characters to mesh color printing, so as to better show the richness and delicacy of label images.

2. In terms of material use, it has gradually developed from paper to film and special materials, which not only makes printed labels more beautiful, but also improves the water and moisture resistance, high temperature resistance, wear resistance, tear resistance, etc. of labels.

3. In terms of the use of printing ink, due to environmental protection, solvent based printing ink will gradually be replaced by water-based printing ink, and UV printing ink will also be widely used. Because UV printing ink is dry in the form of curing, there is no harmful gas generation, and there is basically no pollution to the environment.

4. The processing method has developed from simplicity to complexity and integration, from single printing and multiple post processing to printing and post processing integration, so that printing, hot stamping, polishing, punching, die cutting and other processes can be completed online at one time.

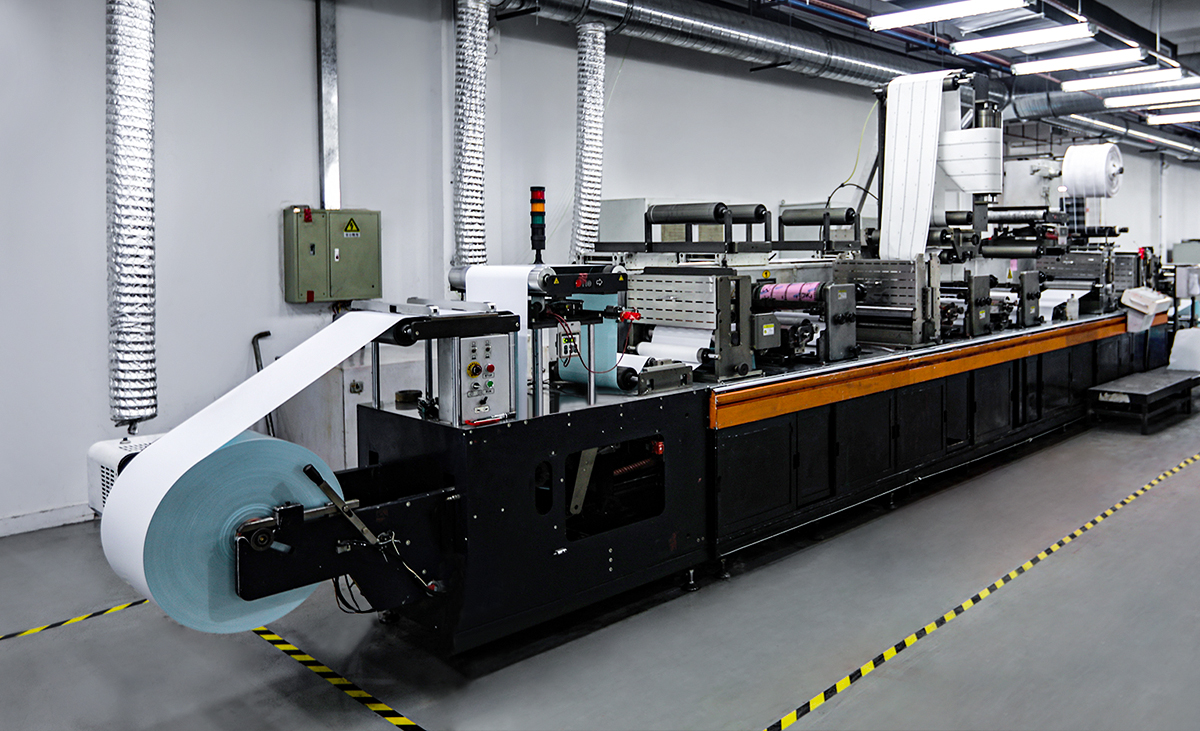

5. The function of the equipment has developed from single printing to combined printing, that is, a machine has multiple functions such as embossing, flexography, gravure printing and screen printing, and can be printed on a label in multiple ways at the same time.

All round competition

At present, the main production enterprises in the label market have more than 20 brands, which can be roughly divided into foreign-funded enterprises, state-owned enterprises, township individual enterprises, etc. From the perspective of the pattern, the foreign-funded enterprises represented by Aili have rapidly expanded their market share with their advanced production technology, stable quality, excellent services and sufficient funds. The state-owned enterprises are sandwiched between medium and high-grade foreign-funded enterprises and low-grade township individual enterprises, which are greatly affected by the market. Although the quality is unstable, due to the good foundation and advanced equipment, they will develop to a certain extent and occupy a certain market share after continuous reform of the system and market positioning. At present, due to historical reasons, individual township enterprises have a large market share due to their geographical advantages. However, most of them only pursue short-term interests without good equipment, stable quality, innovative technology and sufficient funds. In the era of international competition, although some enterprises will compete in the market due to their upgrading and continuous reform, others will be gradually eliminated by the market due to various reasons.

Other expired and scrapped products imported from Europe, America, Japan and other countries through gray channels will temporarily hit the market due to extremely low prices and gain a certain share, but from the perspective of long-term stable development, they will be eliminated by printing plants and end-users. The competition in the label market is all-round, including product competition, service competition, brand competition and speed efficiency competition.

Competition of products

Whether the product quality is stable, whether the product series is complete, and whether the product application field is rich. Due to the complex multilayer structure of adhesive, the basic "sandwich" structure: surface material, adhesive and backing paper, as well as the coating layer between surface material and adhesive, and the silicon coating layer between adhesive and backing paper, any quality or coating problems in any of these links will ultimately affect the quality of adhesive labels. Therefore, stable raw material quality, advanced coating technology and excellent production control management will play a decisive role. In addition, advanced development technology and R&D capability will affect the product series, application fields and functions.

Competition for services

The establishment of pre-sales service can effectively transform customer order information into production. The improvement of distribution network, especially the distribution system in economically developed areas and highly competitive areas, directly affects which supplier the printing factory orders to. The constant introduction of value-added service projects, such as increasing coil length, reducing joints, customization of customer needs, are all continuous extensions of services. With products of the same quality, service will easily become a decisive factor. Improving the service level requires cost and rich management experience, which will continue to be reflected in the future competition.

Brand competition

Today is the era of focusing on brands. When the differences between suppliers in product quality, price, service and other aspects gradually shrink, the brand effect will play a guiding role. The quality of the employees in the label industry has been constantly improved, appearing in a professional image. We should not only deal with customers' business arrangements, but also have the ability to solve customers' problems in printing. At the same time, we should have more professional product knowledge to help customers solve problems in product design and production processes. Only professional companies can cultivate professional talents. A good brand will bring more commitment and confidence to customers in this regard. Strong market penetration has not only established an influence among customers in the printing industry, but also penetrated into users who ultimately use labels in various industries, such as P&G, Kodak and other companies. Establish a brand among direct customers and end-users, assist direct customers to better serve end-users, and solve various needs and problems.

Competition for speed and efficiency

The collection and feedback of market information, on-demand production and supply capacity, production efficiency, new product R&D speed, etc. all reflect the competition of speed and efficiency, and also reflect the comprehensive strength of the enterprise itself.

Customers are more willing to see that label suppliers can meet their fleeting business opportunities with faster speed. In the future competition, the speed and efficiency of market, sales, production, distribution and R&D will bring huge competitive advantages and unlimited business opportunities to label suppliers.

Tel.: +86-0755-82471177, +86-0755-27360110

Address: Building B and Building 101, No.189, Tengfeng Avenue, Fenghuang Community,

Fuyong Street, Bao'an District, Shenzhen

Dongguan Factory

Tel.: +86-13509663610

Address: No. 10, Wangniudun Xinlian Road, Wangniudun Town, Dongguan City

(Newton Intelligent Manufacturing Industrial Park)